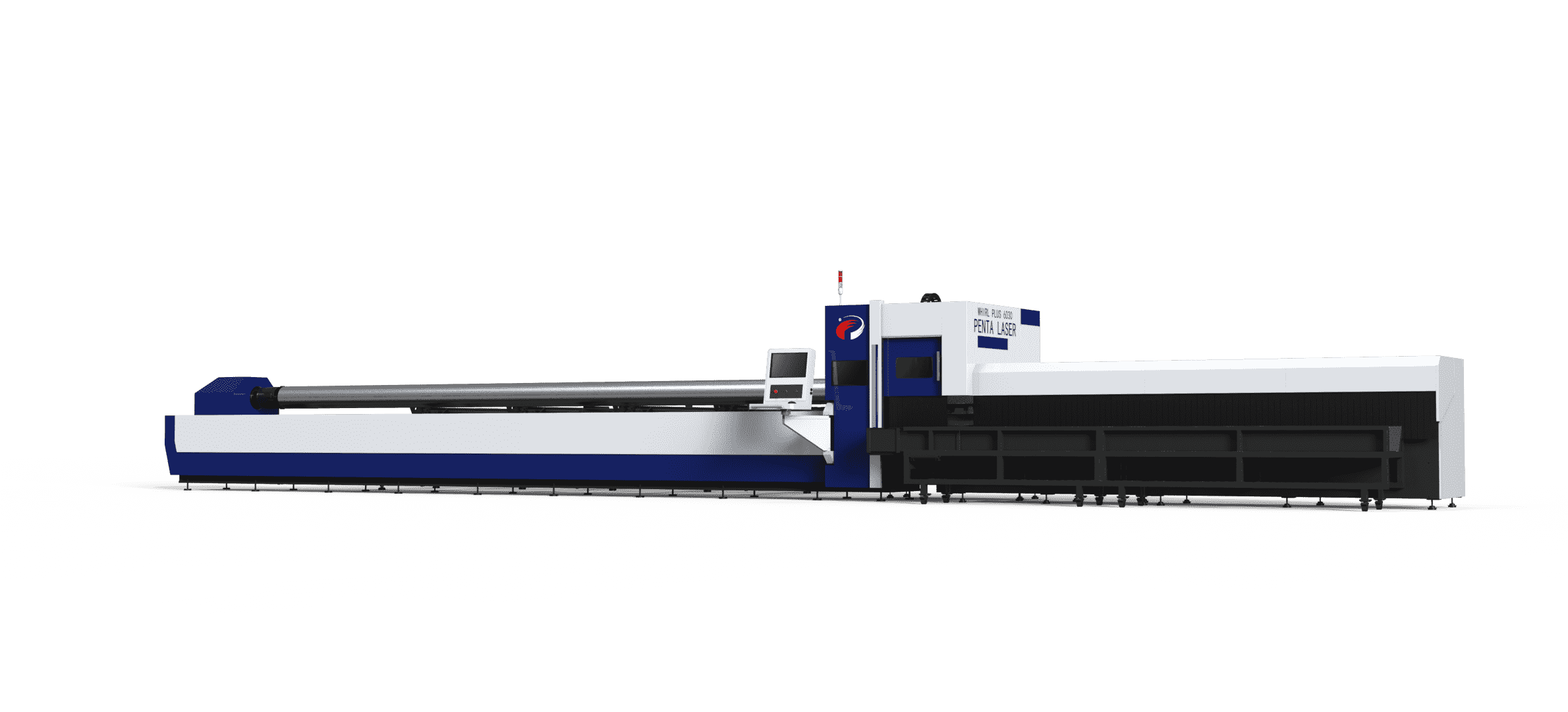

Description

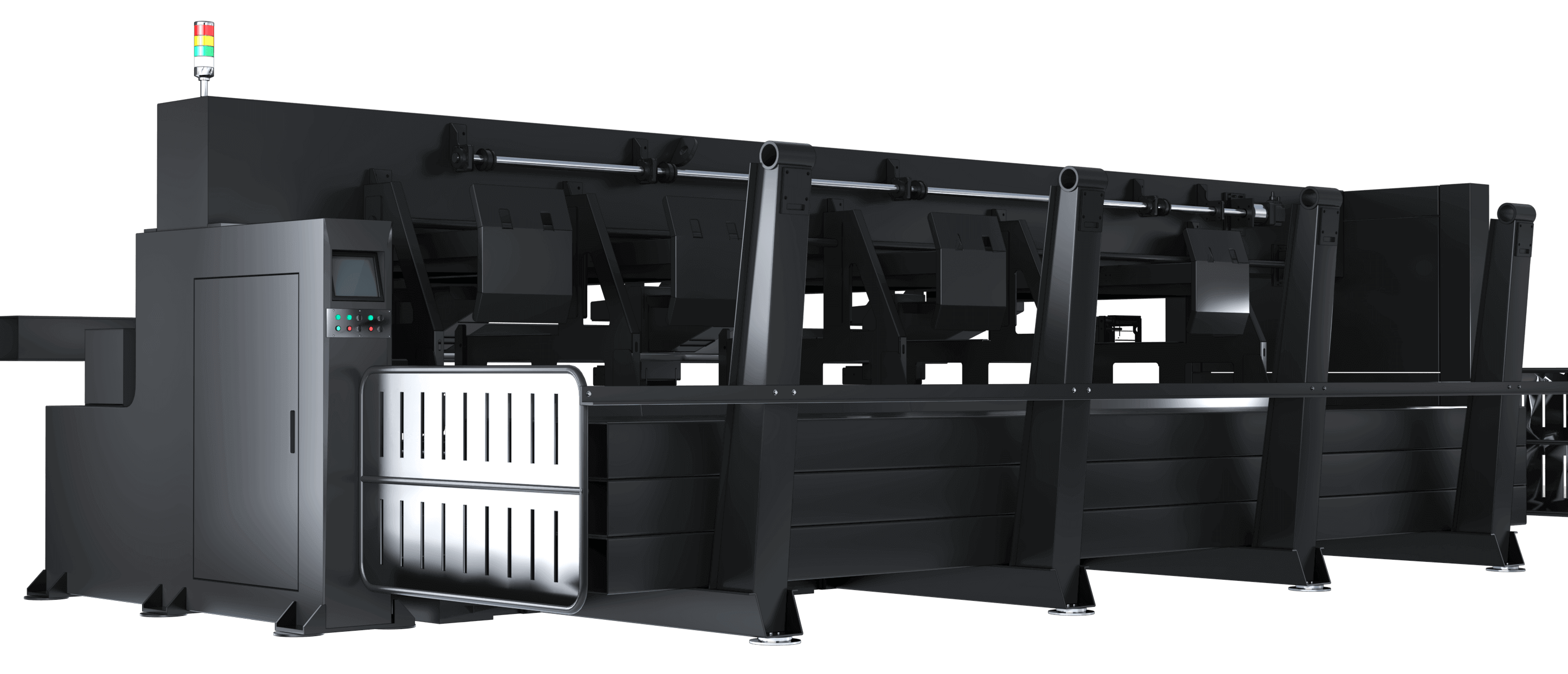

Auto Loading System Optional

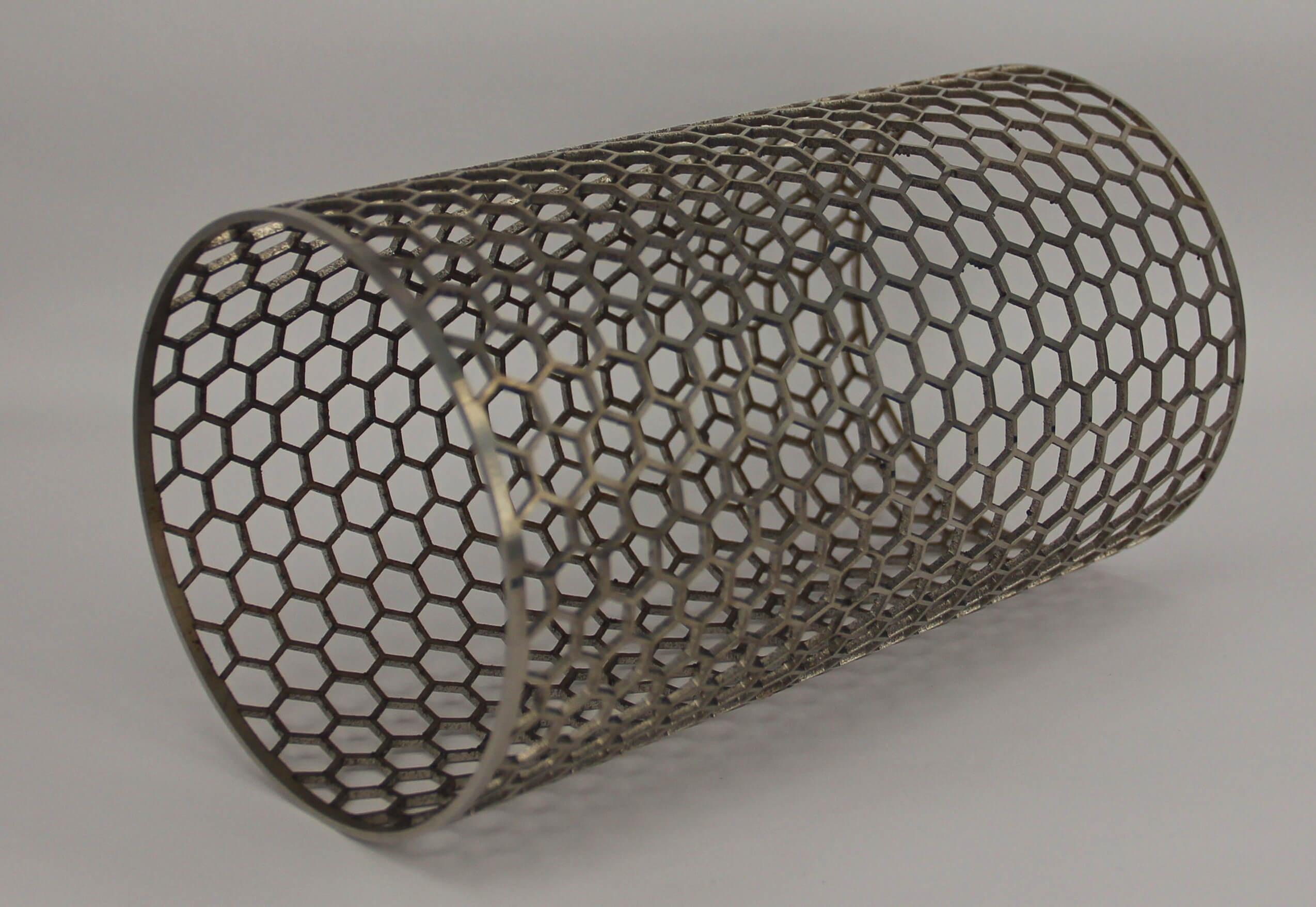

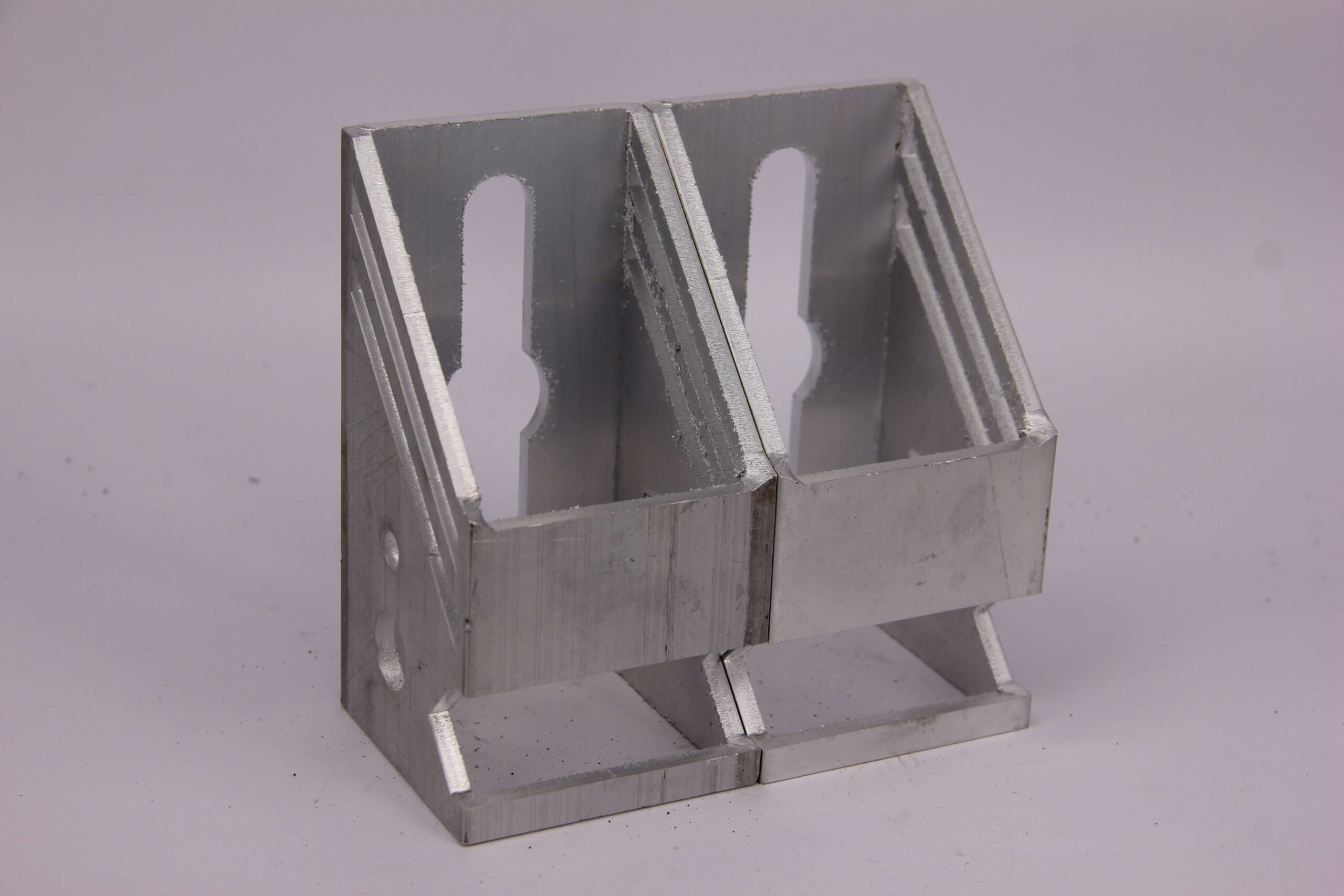

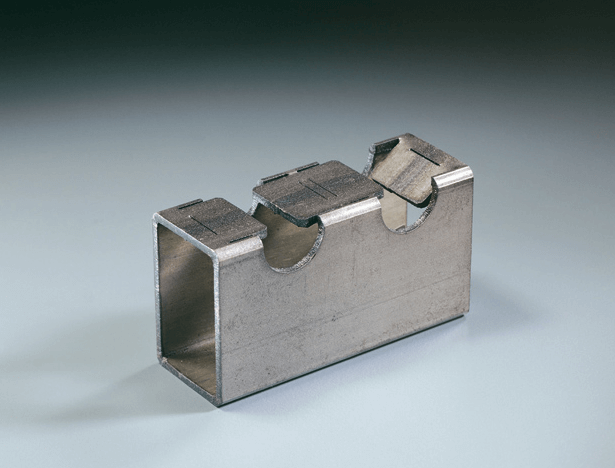

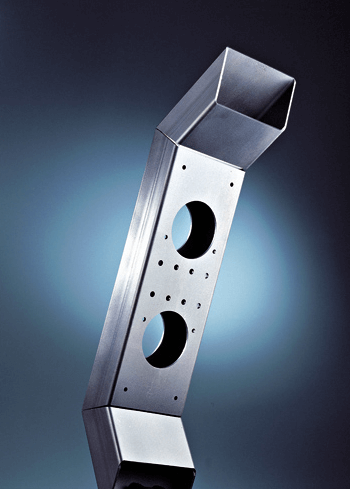

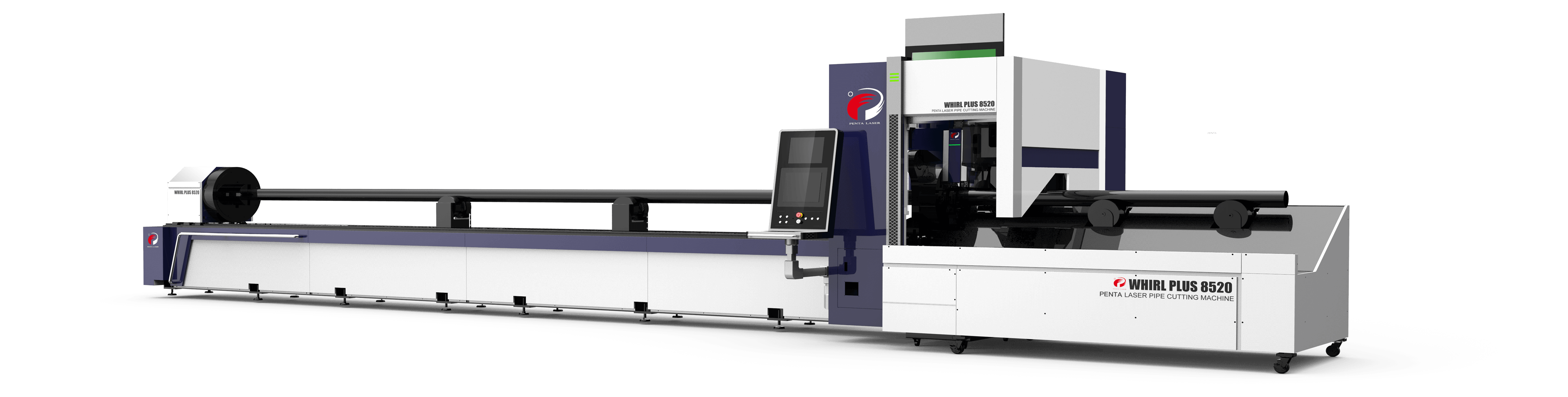

Whirl-Plus mainly applies for processing round tube, square tube, oval tube and other shaped products. Comparing with conventional cutting methods, it works flexibly to decrease new products developing cycle since no mold is required. Automatic loading system available, for decreasing labor cost, increasing cutting efficiency.

Intelligent Fixture

Automatic clamping and centering, ensure long pipe feeding accuracy, high cutting precision and excellent efficiency. Improved auxiliary equipment control system, including the functions of scrap plate turning, feeding support, automatic unloading of the tail material etc, to ensure that the equipment can complete automatic cutting control.

Product Parameters

| Laser power | 1000W-3000W(Optional) |

| Processing format (length * width) | 8500mm*560mm*300mm |

| Maximum acceleration | 1.0G |

| Pipe diamater range | 20mm-100mm |

| Rotation axis speed | 120m/min |

| Max pipe weight | 300Kg |

| Rotation axis A\C\P travel | 360 |

| Straight axis re-positioning accuracy | ±0.03mm |

| Linear acceleration | 1G |

| Rotation axis maximum speed | 120rpm |

| Rotation axis re-positioning acc | ±8 Arc-minute |

| Laser Source | Raycus/IPG |

| X Travel | 8500mm |

| Y Travel | 560mm |

| Z Travel | 300mm |