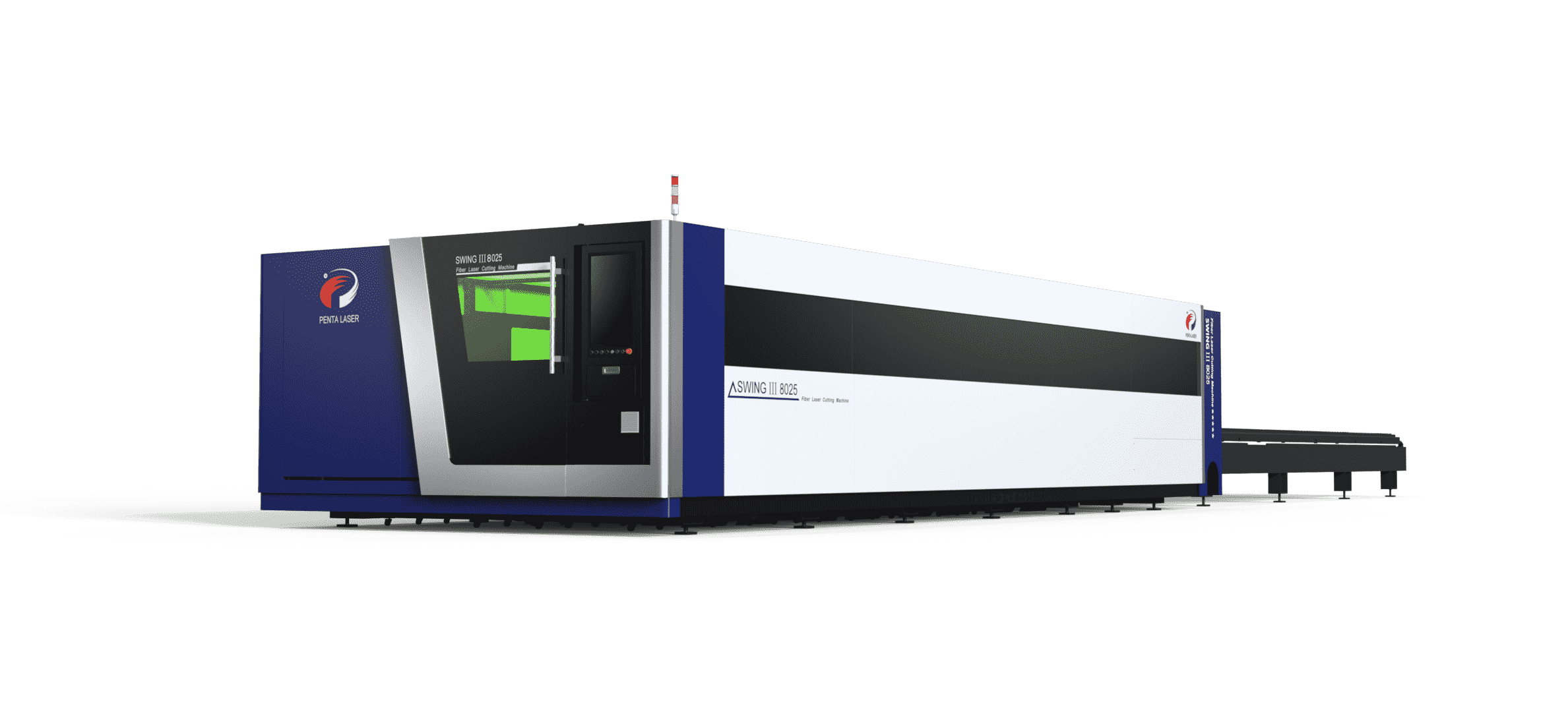

Description

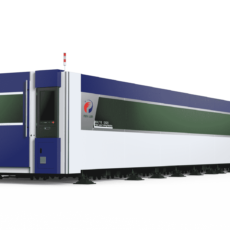

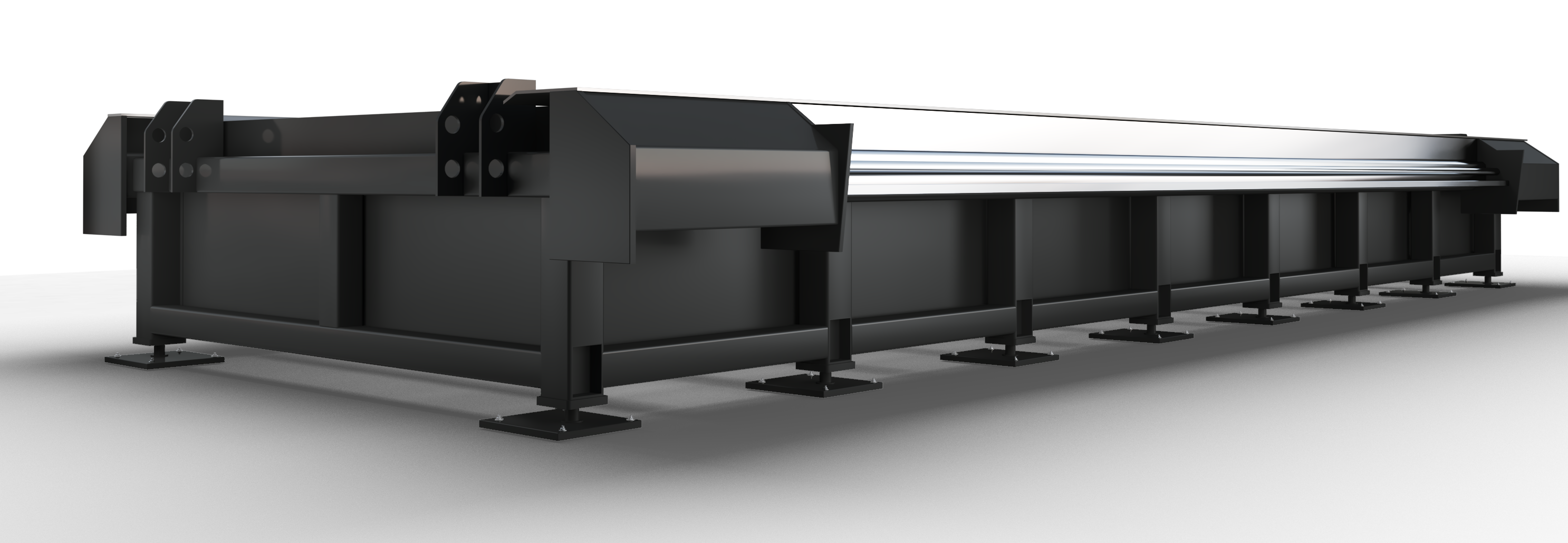

Machine Design And Manufacture

Machine tools adopts heat treatment and thermal protection and automatic lubricating device to reduce heat absorption of machine tools, guarantee machine precision in a long life run; Excellent dynamic performance, high precision and fast speed, the efficiency improved about 20%-40% than other same machines.

Machine tools adopts heat treatment and thermal protection and automatic lubricating device to reduce heat absorption of machine tools, guarantee machine precision in a long life run; Excellent dynamic performance, high precision and fast speed, the efficiency improved about 20%-40% than other same machines.

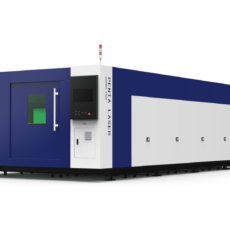

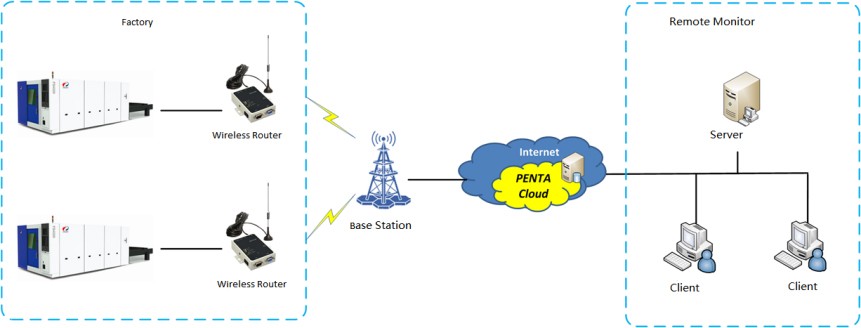

Remote Control and Maintenance System

Based on the Internet of things technology and cloud computing, Penta Laser set up a remote monitoring management system based on cloud platform, to provide accurate products and business support through the remote access of data information, data analysis and processing, control the real-time product situation, timely find product failure, enhance the service efficiency and quality. After-sales response time reduced by 5% – 10%. After-sales troubleshooting time reduced by 10% – 15%. After-sales resolution rate increased 5%. After-sales customer satisfaction increased 15% – 20%.

Based on the Internet of things technology and cloud computing, Penta Laser set up a remote monitoring management system based on cloud platform, to provide accurate products and business support through the remote access of data information, data analysis and processing, control the real-time product situation, timely find product failure, enhance the service efficiency and quality. After-sales response time reduced by 5% – 10%. After-sales troubleshooting time reduced by 10% – 15%. After-sales resolution rate increased 5%. After-sales customer satisfaction increased 15% – 20%.

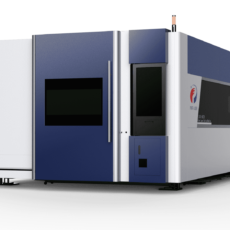

Product Parameters

| Laser power | 6000W to 12000w (optional) |

| Processing format (length * width) | 4000mm * 2000mm (optional) |

| Maximum acceleration | 1.5G |

| Maximum running speed | 120m/min |

| The weight | 10500kg |

| Repeated positioning accuracy | ±0.01 |

| Machine tool bearing | 2355kg |

| Appearance size ( length width height ) | 11500mm×3500mm×2500mm |